Written by Bryan Sim, Business Development, AnjouHealth

In Singapore, it is easy to assume that workplaces are “quite safe” because of strong regulations, regular audits, and a generally high level of Workplace Safety and Health (WSH) awareness. Yet after working closely with offices, healthcare providers, logistics operations, and industrial sites, it is clear that the most common workplace safety hazards in Singapore are often everyday issues that have been normalised over time.

A wet pantry floor.

A cluttered walkway.

A staff member sitting in discomfort for months.

A “quick” manual handling task that skips assessment.

These routine situations are exactly where risk builds quietly.

The problem: common hazards in Singapore workplaces

A question often posed by EHS officers and safety teams is: “What are the most common workplace safety hazards in Singapore?”

Even in office environments, national WSH guidance frequently highlights hazards such as slips, trips, and falls; falling objects; poor ergonomics; manual handling; and prolonged static postures. In higher-risk sectors such as construction, manufacturing, logistics, and facilities management, common workplace safety hazards in Singapore also include machinery and moving equipment, work at height, vehicular movement, and exposure to electrical and chemical hazards.

The reality is that most hazards are not rare or extreme; they are routine.

Why do these common hazards cause the most harm

Because these hazards feel familiar, they are often overlooked until they result in:

- More frequent minor injuries and discomfort

- Recurring musculoskeletal pain and fatigue

- Higher absenteeism and reduced productivity

Singapore’s Workplace Safety and Health Act requires employers to take reasonably practicable measures to ensure employees’ safety and health, which includes identifying hazards and managing risks before incidents happen. This is why hazard risk assessments remain central to managing common workplace safety hazards in Singapore.

Hazards vs risks: a quick refresher

- A hazard is anything with the potential to cause harm.

- A risk is the likelihood and severity of that harm occurring.

For example, a slippery floor is a hazard, while the chance of someone slipping and being injured is the risk. Under the WSH (Risk Management) Regulations, employers must systematically identify hazards, assess risks, and implement controls.

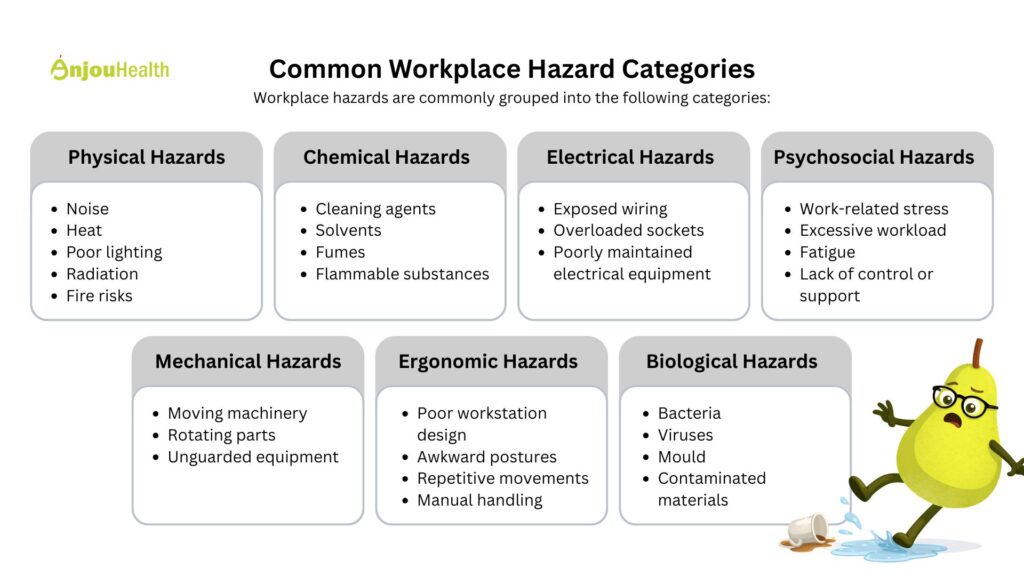

Main types of workplace hazards

In Singapore, workplace hazards are commonly grouped into the following categories:

- Physical hazards: noise, heat, poor lighting, radiation, and fire risks.

- Mechanical hazards: moving machinery, rotating parts, and unguarded equipment.

- Electrical hazards: exposed wiring, overloaded sockets, and poorly maintained equipment.

- Chemical hazards: cleaning agents, solvents, fumes, flammable substances, and poorly labelled chemicals.

- Biological hazards: bacteria, viruses, mould, and contaminated materials.

- Ergonomic hazards: poor workstation design, awkward postures, repetitive movements, and manual handling.

- Psychosocial hazards: work‑related stress, excessive workload, fatigue, and lack of control or support.

These categories underpin the most common workplace safety hazards in Singapore, regardless of industry.

Are ergonomic risks considered workplace safety hazards?

Yes. Ergonomic risks are recognised as workplace hazards and are frequently linked to work‑related musculoskeletal disorders in Singapore. Issues such as prolonged static postures, poorly designed workstations, repetitive tasks, and manual handling are widely highlighted in WSH guidance as key contributors to discomfort and injury.

The challenge is that ergonomic hazards usually cause gradual harm rather than immediate injuries, so they are often underestimated.

Common workplace safety hazards seen most often in Singapore

From on‑site observations and national statistics, the same patterns appear across many workplaces.

Frequent hazards across sectors

- Slips, trips, and falls – wet floors, loose cables, cluttered walkway, and uneven surfaces.

- Poor workstation ergonomics – unsuitable chairs, misaligned monitors, laptop use without peripherals, and prolonged sitting without breaks.

- Manual handling risks – lifting cartons, moving equipment, carrying supplies, or handling patients without proper assessment or aids.

- Work at height – standing on chairs, unstable stools, or makeshift platforms instead of proper access equipment.

- Machinery and equipment hazards – inadequate guarding, unsafe maintenance practices, and lack of lock‑out procedures.

- Chemical and indoor environmental risks – improper storage or use of cleaning chemicals and poor ventilation leading to exposure to fumes and vapours.

- Psychosocial risks – high workload, constant time pressure, fatigue, and insufficient recovery, which are increasingly recognised in WSH discussions.

Slips, trips, and falls, machinery incidents, and being struck by moving objects consistently rank among the top causes of workplace injuries in Singapore.

Key steps in a hazard risk assessment

A practical hazard risk assessment typically follows these steps:

- Preparation – define scope, understand work processes, and review incident history.

- Task analysis – break activities into clear steps.

- Hazard identification – look for hazards across all categories, including ergonomic and psychosocial.

- Risk evaluation – assess likelihood and severity.

- Risk control – use the hierarchy of controls: elimination, substitution, engineering, administrative controls, and personal protective equipment. Ensure workers understand risks and control measures.

- Review and update – after changes, incidents, or at regular intervals.

These steps align with guidance for managing common workplace safety hazards in Singapore under the risk management framework.

Who is responsible, and when should assessments be done?

Employers are ultimately responsible for ensuring hazards are identified and risks are managed, but effective risk management involves management, supervisors, employees, and safety personnel. Risk assessments are most effective when the people who understand the work on the ground participate actively.

Assessments should be carried out before new work begins, after process or layout changes, following incidents or near misses, when employees raise concerns, and periodically thereafter. Leading organisations treat the assessment of common workplace safety hazards in Singapore as an ongoing process, not just a compliance exercise.

JSA, SWP, and hazard risk assessment

- A workplace hazard risk assessment identifies hazards and determines controls.

- A Safe Work Procedure (SWP) describes how a task should be carried out safely in practice.

- A Job Safety Analysis (JSA) focuses on specific jobs or tasks, often used on‑site before work starts.

These tools support one another to manage common workplace safety hazards in Singapore, rather than replacing each other.

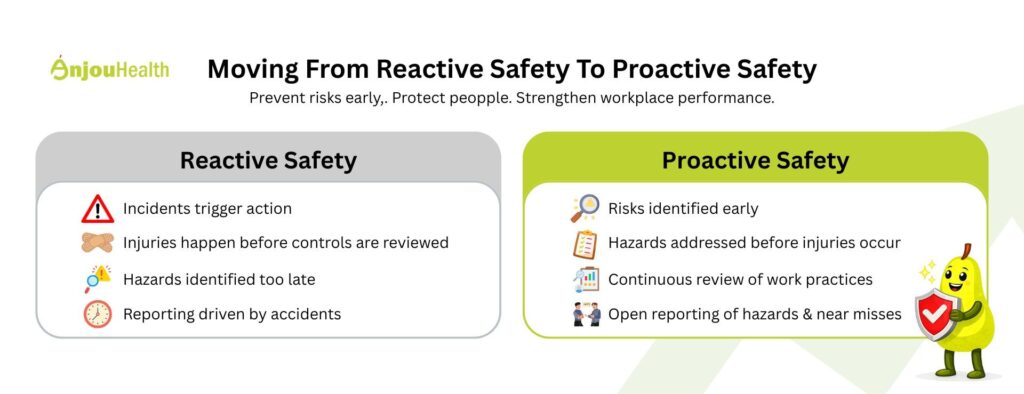

Moving from reactive to proactive safety

Organisations that handle safety effectively tend to:

- Identify common workplace hazards early, before they result in injuries.

- Encourage employees to report hazards and near misses without fear.

- Review workstations, workflows, and staffing proactively, including ergonomic and psychosocial factors.

This proactive approach supports compliance with WSH regulations and improves productivity, morale, and long‑term workforce health.

A practical self‑check

As you walk through your workplace, consider:

- Where are our main slip, trip, and fall risks?

- Are workstations adjusted to fit people, or are people forced to adapt?

- Are manual handling tasks assessed and supported, or just “managed informally”?

- Do employees feel encouraged and safe to report hazards before injuries occur?

If you are unsure, that is not a failure; it is simply your starting point.

Ready to Address Common Workplace Safety Hazards in Your Workplace?

If you are concerned that common workplace safety hazards in your workplace may be going unnoticed, structured support can help. At AnjouHealth, we assist organisations with workplace hazard and ergonomic risk assessments, as well as practical recommendations that go beyond compliance checklists.

Reach out to start a proactive conversation about workplace safety before minor hazards turn into major problems.

Frequently Asked Questions (FAQs)

1. What are the most common workplace safety hazards in Singapore?

Common workplace safety hazards in Singapore include slips, trips, and falls, poor ergonomics, manual handling risks, work at height, machinery hazards, chemical exposure, and psychosocial risks like stress and fatigue.

2. Why do common hazards cause so many workplace injuries?

Because they feel routine, common hazards such as cluttered walkways, poor posture, or rushed manual handling are often overlooked until they lead to injuries, absenteeism, and productivity loss.

3. Are ergonomic risks considered workplace safety hazards in Singapore?

Yes, ergonomic risks like prolonged sitting, awkward postures, and repetitive movements are recognised as workplace hazards and are linked to musculoskeletal disorders and discomfort.

4. Who is responsible for managing workplace safety hazards?

Employers are ultimately responsible under the Workplace Safety and Health Act, but effective risk management also involves management, supervisors, employees, and designated safety personnel.

5. How often should workplace hazard risk assessments be carried out?

Risk assessments should be done before new work begins, after changes to processes or equipment, following incidents or near misses, when employees raise concerns, and at regular intervals.

6. What are the key steps in a workplace hazard risk assessment?

Key steps include preparation, task analysis, hazard identification, risk evaluation, implementing controls using the hierarchy of control, communicating with workers, and reviewing the assessment periodically.

7. What is the difference between a risk assessment, JSA, and SWP?

A risk assessment identifies hazards and evaluates risks, a Job Safety Analysis focuses on specific tasks, and a Safe Work Procedure documents how to perform those tasks safely in practice.